Docket 2025-1 has profoundly impacted the less-than-truckload (LTL) industry. With many items in the National Motor Freight Classification® (NMFC®) now using the Freight Classification Development Council’s (FCDC) standard 13-subprovision full-density scale, packaging plays an even greater role in shipment classification.

Proper packaging not only provides superior protection that mitigates claims, but can also influence freight class—and, by extension, shipping cost. When done right, it’s a win-win: fewer damages for the shipper and stronger trust with the carrier.

Understanding Density and Packaging Impact

To calculate density, use the total weight and cubic feet of the shipment or handling unit. When measuring, the NMFC requires using the shipment’s extreme dimensions—that means including all packaging or packing forms such as pallets, crates, or “do not stack” cones.

Larger cubes generally result in lower densities—and therefore higher classes and costs—though additional packaging can sometimes reduce total costs by preventing damage and reshipments. The key is balance: enough protection to prevent loss, but not so much that it drives up dimensional costs.

A Real-World Example: Balancing Cost and Protection

Let’s use an example of a shipper tendering an expensive electronic product in a fiberboard box, with sufficient interior packaging. The commodity is classified under an NMFC item subject to the FCDC’s 13-subprovision full-density scale, and the shipper is deciding whether or not to palletize the box. Palletization improves mechanical handling and reduces the risk of damage during transportation. However, adding a pallet in this example increases the shipment’s cubic footprint, therefore lowering the density and raising its class (and potential costs).

Ultimately, the right choice depends on your acceptable damage threshold. What is determined to be acceptable varies, as it depends on what type of damage occurs, where it occurs, and the severity of the damage. Over-packing can be costly and may outweigh product value on larger shipments, but for a single high-value item, investing in a pallet may be worthwhile. Shippers and carriers who collaborate on packaging strategies often achieve the best balance between cost and protection.

Packaging Questions That Pay Off

Once shippers identify their acceptable level of risk, they should evaluate other packaging and documentation practices that affect classification accuracy and efficiency:

- Do fiberboard boxes meet NMFC Item (Rule) 222 requirements? This includes limits on dimensions and weights by fiberboard type. Boxes manufactured in the U.S. should display a Box Manufacturer’s Certificate (BMC) confirming compliance.

- Is my pallet load tightly configured with minimal void space? Avoid overhang and “shipping air”. Condensed, secure configurations save space and cost for both shipper and carrier.

- Are weights and dimensions accurately recorded on Bills of Lading (BOLs)? Correct data ensures proper density classification, prevents costly reweighs, and saves time for everyone involved.

Small Changes, Big Results

Attention to packaging and documentation details promotes fairness, accuracy, and efficiency—saving time and reducing costs for both parties. Over time, those efforts build stronger, more reliable business relationships.

For more information, review NMFTA’s Packaging Guide for key highlights of major NMFC Packaging Rules. NMFTA also hosts biannual Packaging Webinars detailing freight classification, Packaging Rules, and real-world examples of compliance. You can register for our next series in 2026. .

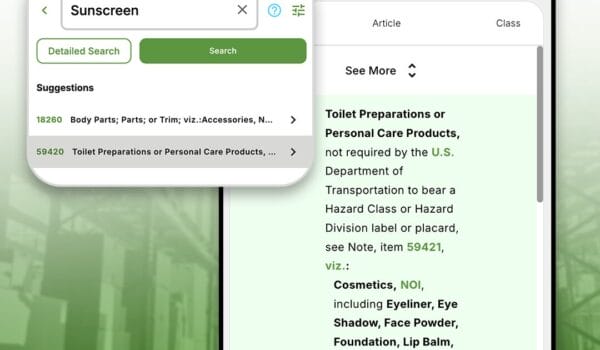

Finally, to stay current on all classification and Packaging Rule updates and amendments in real time, subscribe to ClassIT+™, the official online version of the NMFC.

Remember: Small packaging changes can lead to big savings, better protection, fewer claims, and stronger carrier relationships. Check out the resources above to see how NMFTA can help you!